An encoder is an ultra-precise sensor that goes into the joints of a robot's arm. It senses the direction and speed of rotation of the motor, helping precise operation. RS Automation, a company specializing in industrial robot motion controllers, recently succeeded in developing the world's first '25-bit class' encoder. CEO Kang Duk-hyun said, "The 25-bit encoder means that it can be recognized by dividing 2 to 1/25 square (33.55 million)." The RS automation technology is one step higher than the bit class.”

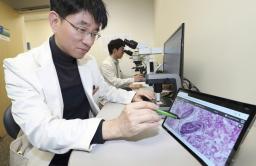

Representative Kang Duk-hyun explaining the ultra-precision sensor encoder that fits in the joint part of the robot arm (provided by RS Automation)

RS Automation, a listed company on the Kosdaq market, is Korea's top manufacturer of motion controllers for industrial robots (50% market share). It mainly produces ultra-precision sensor encoders, drives that act as muscles that transmit power to robots, and brain function controllers. Last year, it recorded sales of 113.4 billion won (about 11 billion yen) and operating profit of 2.8 billion won (about 272 million yen). The company's encoders, drives, and controllers are exported to 21 countries around the world, including the United States, Japan, Germany, and China, all of which are robot powerhouses. About 100 major companies around the world, including South Korea's Samsung Electronics, Hyundai Motor, LG Display, U.S. Rockwell, and Germany's Semikron, are our customers. Kang said, “Robot motion controllers are used to control robots not only in semiconductor factories that require fine and precise control, but also in large-scale industrial sites such as displays and automobiles.” Another strength is the ability to simultaneously control multiple robot joints with a single drive. "One drive can control 3 to 6 robot joints, and space efficiency is excellent," he emphasized. In recognition of these technological strengths, the company was selected as one of the World Class 300 and 100 small and strong companies in materials, parts, and equipment. RS Automation was formerly known as Rockwell-Samsung Automation. The company was established in 1995 by Samsung Electronics' automation team in collaboration with Rockwell Automation, a US robotics company. Representative Kang, who used to be an engineer at Samsung Electronics, acquired shares and became a professional manager and the largest shareholder (equity ratio 29.35%). Corona has become a hindrance to growth. Although the company made a preemptive large-scale investment in human resources and equipment, the client company's smart factory equipment investment was delayed, and the originally anticipated sales did not occur. In 2020, it posted an operating loss of 1.6 billion won (about 155.3 million yen). However, the securities industry expects that double-digit sales growth will be possible this year after successfully turning profitable for the first time in a year last year. “In 2020, there was a lot of investment due to the expansion of the factory and the recruitment of master’s and doctoral level researchers, but the coronavirus limited growth,” said Kang. He continued, "You can see it as a growth path that accompanies a leap forward to become a world-class small and powerful company." Through continuous research and development, RS Automation is determined to widen the technological gap in robot motion controller technology. Through this, it has set a goal of achieving sales of 200 billion won (about 19.4 billion yen) and operating profit of 20 billion won (about 1.9 billion yen) in 2025. “We will raise the ratio of exports from the current 30% to 70% in the future, and increase the operating margin to 10%,” Kang said, adding, “Leaping forward to become the world’s best company in the robotics field.” (Pirasawa)

Kim Jin Won